Opening the Power of Engines: A Comprehensive Overview to Efficiency and Performance

Recognizing the detailed technicians of engines is crucial for both efficiency lovers and daily vehicle drivers. By taking a look at crucial metrics such as horse power and torque, one can appreciate how tuning strategies improve effectiveness while dealing with environmental problems. Moreover, regular upkeep plays a pivotal function in sustaining optimal performance in time. As the automobile landscape changes towards electrification and advanced technologies, the inquiry arises: exactly how can we effectively adjust to these modifications while optimizing engine capacities? The answers might redefine our method to engine performance and effectiveness in manner ins which are both informing and essential.

Understanding Engine Fundamentals

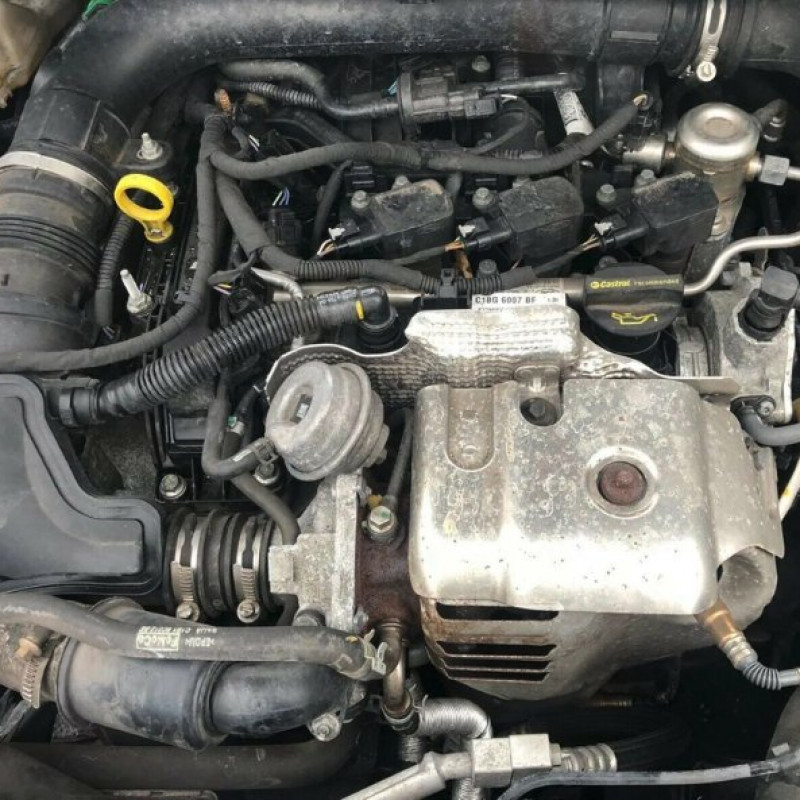

What makes up the essential auto mechanics of an engine? At its core, an engine is an equipment designed to convert gas right into power through a collection of controlled explosions or combustion processes. The key components include the cyndrical tube, piston, crankshaft, camshaft, and valves. The cylinder acts as the chamber where combustion occurs, while the piston relocates within the cylinder to transform the energy from burning right into linear activity (ford fiesta engine).

The crankshaft after that changes this straight activity right into rotational energy, which eventually powers the automobile. The camshaft regulates the opening and closing of the shutoffs, controling the consumption of air and gas and the expulsion of exhaust gases. In addition, the engine counts on a very carefully calibrated fuel-air mix, ignition system, and cooling system to make sure optimal efficiency and effectiveness.

Understanding engine fundamentals also includes identifying the significance of engine cycles, such as the four-stroke cycle, which consists of consumption, power, exhaust, and compression strokes. Each phase is critical in making sure the engine operates efficiently and efficiently. Proficiency of these basic technicians prepares for exploring more complex engine dynamics and efficiency metrics, necessary for maximizing both power result and efficiency.

Key Performance Metrics

Trick efficiency metrics are important for examining an engine's effectiveness and power result, offering important insights for both makers and customers. These metrics serve as benchmarks for engine efficiency, permitting notified decisions in style, purchasing, and production.

Among the key metrics is horsepower, which quantifies the engine's ability to perform work over time. Torque, gauged in pound-feet, is another crucial statistics that indicates the engine's rotational force, directly influencing acceleration and hauling capacity. Fuel effectiveness, usually determined in miles per gallon (MPG) or litres per 100 kilometers (L/100km), examines just how effectively the engine transforms fuel into motion, impacting functional costs and environmental factors to consider.

Furthermore, thermal performance actions exactly how well an engine transforms gas energy right into valuable job, exposing understandings right into energy losses mostly through warm. Emission levels, consisting of CO2 and NOx, are additionally crucial, showing the engine's environmental effect and compliance with regulatory standards.

Tuning Strategies for Performance

Tuning methods play a significant role in boosting engine efficiency by maximizing performance metrics determined in earlier discussions (ford fiesta engine). Various approaches exist to fine-tune an engine, each adding to improved fuel economy and useful content minimized discharges

One reliable technique is readjusting the air-fuel ratio, making certain the engine runs within the optimum combustion routine. A leaner mixture can boost fuel performance, but it needs to be balanced to avoid misfires or engine knock. Additionally, reprogramming the engine monitoring system can rectify specifications such as ignition timing, which additionally improves effectiveness while keeping power output.

Another essential technique entails modifying the intake and exhaust systems. Updating to high-performance air filters and exhaust headers can lower back pressure, helping with far better airflow. This enables the engine to take a breath more openly, bring about boosted burning performance.

Furthermore, the implementation of innovative adjusting tools, like dyno screening, gives precise data that makes it possible for targeted modifications. Consistently keeping an eye on these performance metrics makes certain that tuning efforts produce the preferred efficiency end results. Jointly, these strategies not just strengthen engine efficiency but also add to lasting sustainability in engine procedures.

Maintenance for Ideal Efficiency

Regular engine upkeep is vital for accomplishing ideal efficiency and long life. A properly maintained engine not just operates successfully yet additionally minimizes the threat of costly repair work and malfunctions. Key components requiring regular focus consist of oil, filters, belts, and ignition system.

Altering the engine oil at suggested periods is important, as oil lubes relocating components and prevents overheating. Similarly, changing oil and air filters makes certain that contaminants do not impair engine feature. Ignoring these elements can result in decreased efficiency and potential engine damage.

Furthermore, checking and changing used belts and hoses is crucial to avoid abrupt failings. Timing belts, particularly, must be replaced according to the maker's schedule to stay clear of tragic engine damages.

Flicker connects should likewise be checked and replaced as essential, since they play a crucial role in ignition and gas efficiency.

Future Patterns in Engine Technology

Accepting improvements in modern technology, the future of engine style is poised to reinvent efficiency and effectiveness throughout various applications. Crossbreed and fully electrical powertrains are ending up being increasingly mainstream, providing minimized emissions and boosted gas efficiency.

Moreover, innovations in materials scientific research check my source are bring about lighter, stronger parts that enhance engine performance while reducing power consumption. Advanced production strategies, such as 3D printing, permit for the development of intricate geometries that boost air movement and thermal monitoring, therefore maximizing combustion processes.

Furthermore, the integration of expert system and artificial intelligence is readied to transform engine diagnostics and efficiency adjusting. These modern technologies can assess substantial amounts of information in real time, making it possible for predictive maintenance and tailored performance improvements.

Final Thought

Finally, unlocking the power of engines needs a thorough understanding of their auto mechanics and performance metrics. Carrying out reliable adjusting strategies and adhering to normal upkeep practices considerably improve engine capacities. As the auto landscape advances, embracing future trends in innovation, consisting of electrification and progressed manufacturing, will be crucial for maximizing performance and effectiveness. This detailed method not just advantages fanatics however also adds to sustainable solutions in the world of automotive engineering.

Additionally, the engine counts on a thoroughly adjusted fuel-air mix, ignition system, and cooling down system to make sure optimum performance and effectiveness.

Understanding engine fundamentals likewise involves recognizing the significance of engine cycles, such as the four-stroke cycle, which consists of consumption, compression, exhaust, and power strokes. Mastery of these essential mechanics lays the groundwork for exploring much more complex engine characteristics and performance metrics, necessary for maximizing both power output and efficiency.

Accepting improvements in technology, the future of engine layout is poised to reinvent performance and efficiency throughout numerous applications.

Comments on “Exploring the Benefits of a High-Performance Ford Fiesta Engine”